Gilayo®

The Steel Skeleton

The Future of Modular, Resilient Steel Structures.

We've developed a patented steel frame system that can be used to build virtually ANY size structure. These resulting structures are designed by a builder or architect, fabricated by a local steel fabricator, and built by individuals or construction companies. All you need from us, is the Gilayo® plate to ensure safety and stability of the finished product.

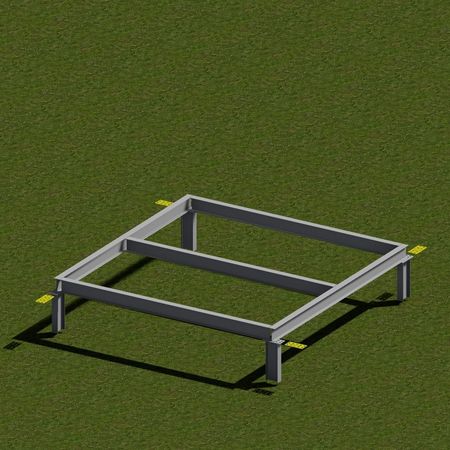

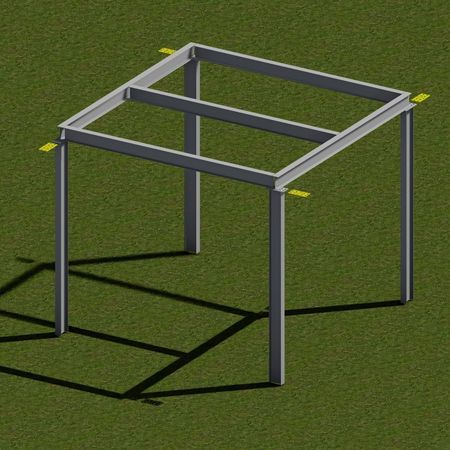

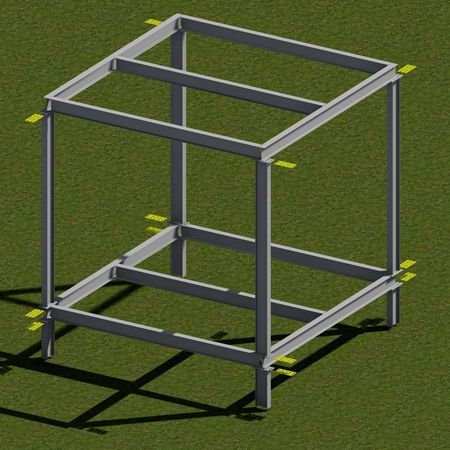

The Foundational Gilayo® Steel Frames

Each steel structure begins with one of the foundational frames below. They can be expanded and modified according to your design project. 70% reduction over traditional construction, ready for finishes.

Deck

$3,000*

Canopy

$4,000*

Living

$7,000*

Imagine What can be Built...

The foundational frame only consists of 3 different beams, 2 different columns, some small clip angles and plates for ANYONE to build...

- A steel structure of any size and shape

- Fully expandable in any direction for infinity

- Immediately available at the least expensive cost of steel possible

- Can be built anywhere in the world, in any seismic, wind, snow load or soil condition

- Can be built without the need for directions in any language, with simply a wrench

- Frames are relocatable and mobile and can be transported in a standard pick-up truck

- Made from 99% recycled material from old cars and scrap metal

The Gilayo® Plate allows you to do all of these things and all the information you need is here on our website.

Sample Expandable ADU Unit Model

Here is just ONE Example of How Gilayo® can Change Construction Forever!

Volume: 2790 cubic ft

Cost: $15,000 USD

Two Cargo Containers

Chemical Free

- Shipping Costs

- Heavy Equipment Required

- Welder Required to Modify

- Difficult to Expand

- Virtually Impossible to Remain Watertight

- 20% Less Volume and Twice The Cost of GILAYO®

VS.

Volume: 3300 cubic ft

Cost: $7,000 USD

GILAYO®

Two Module Canopy

- Fits in Standard Pick Up Truck

- No Heavy Equipment Needed

- No Welder Needed - Erection Can Be Done with Standard Wrench

- Simple to Expand

- Always Remains as One Continuous Structure

- All Beam Flanges Have Holes At 36" o.c. for Non-Bearing, Non-Shear Walls Subject to Regional Construction & Resources

Industries & Use Cases

Steel Subcontractor, Fabrication & Erection

Developers & Contractors

Architects &

Engineers

Disaster Relief & Government

Urban & Rural Applications

Off-Grid & Green Applications

How Much Does it Cost?

MSRP

Full Living Unit (ready for finishes) - $7000

Canopy Only - $4000

Platform Only - $3000

Note: a canopy and platform make up a living unit but can be sold separately.

Our Philosophy

We provide full transparency by sharing our patented design to builders and steel fabricators. We ONLY sell the required Gilayo® plates. Why do we do this? So we can focus on design, development and providing relief where needed. We don't want the added overhead of production and building. This way, we provide an opportunity for builders and steel producers to share the revenue of our proprietary design. They know, that we are doing this for our nonprofit foundation and in their way, they are supporting our amazing causes.

Features and Benefits

Intuitive Design

Pre-fabricated by certified welders so all components fit together easily. No need for complicated schematics. 80% of steel fabrication is done by automated production without human labor.

Durability

This modular framing system can be installed in any terrain, soil condition, seismic load, wind load, snow load. No need for heavy equipment for grading.

No Experience Required

Connections use simple 1/2" diameter bolts with installation by common wrench. Two to three individuals can easily set up a module within a weekend or less.

Cost & Availability

Pre-production components lead to cost reductions and immediate availability. Repetitive beam and column design mean more cost-efficient production and procurement.

Easily Transport

Lightweight components ensure easy transport in a standard pick-up truck. Parts are easily disassembled for relocation.

Expandable

Modules are built to connect so that you can expand your structure, making it even more cost-effective per square foot.

Let's Talk!

Have a question or comment?

Let us know.

Patent Pending

Our Cause

Through our work at the Olive Shed Foundation, we are able to provide humanitarian support, support to youth organizations and various causes we believe in.

All Rights Reserved | Gilayo®

Website designed & managed by: Wordflirt®